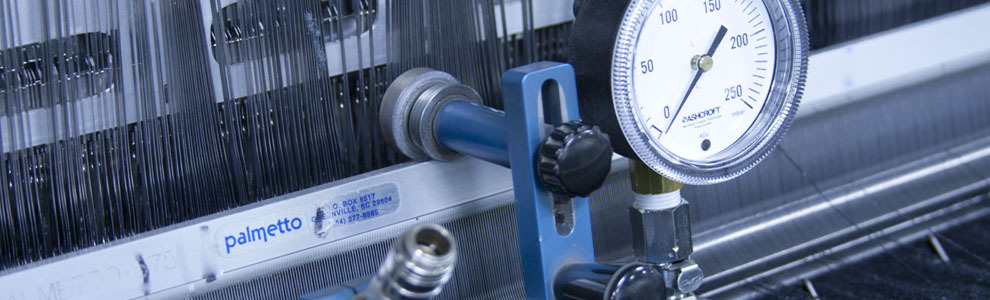

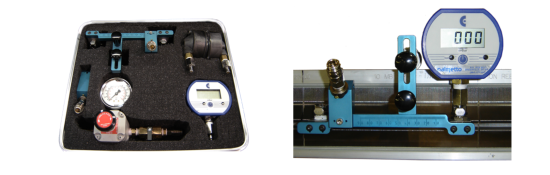

Palmetto Reed offers a Dynamic Air Pressure Gauge that gives you the flexibility of checking Reed Air Flow and relay nozzle settings at the weave machine using the same gauge with just a simple change of the gauge reader at the weave machine. Relay nozzle maintenance is easily performed at the machine with our gauge. The gauge comes with a calibration reed and we also have an air flow technician to provide training for your technicians at your plant location. Consistent pick insertion is critical to weave at the highest level possible and our gauge provides this.

Key features and benefits of the Dynamic Air Pressure Gauge are:

- Quick setup for Airflow Verification

- Air pressure valves for any type of Air Jet Reed

- Read Air Pressure the complete Length of a Reed

- Interchangeable Relay Nozzle Gauge

Why do you need a Dynamic Pressure Gauge?

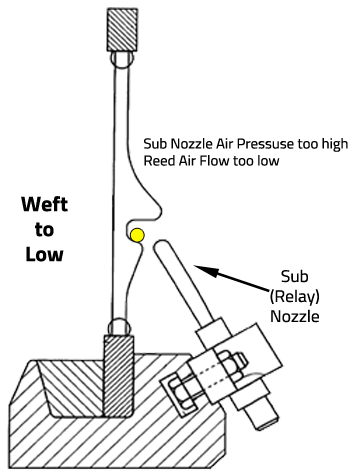

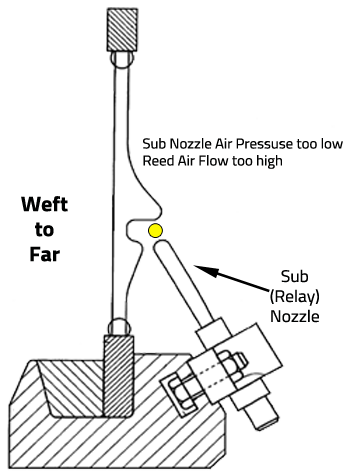

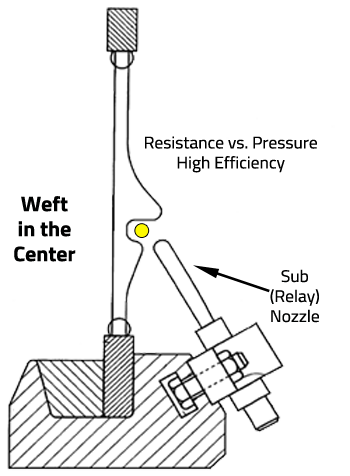

It is necessary that the air flow profile of the reed, as influenced and established by the auxiliary relay nozzles, conform to optimal standards. Periodically, it is necessary to reevaluate the air flow of the reed itself as well as air flow properties as established by the auxiliary air relay nozzles.

Periodic evaluation and calibration of the reed and loom are necessary since a variety of factors influence the air flow properties of the loom. For instance, weaving efficiency may suffer from a dirty or damaged reed, particularly if the reed groove is affected. In addition, an occluded or damaged auxiliary air jet nozzle, a misaligned nozzle, poor air pressure supply, or a damaged solenoid control for the air jet nozzles, may all affect the weaving efficiency.

In a typical air jet loom, the weft is directed by an air jet into the reed groove or channel. Auxiliary air jet nozzles are provided at fixed intervals in a guide path along the reed groove. In order to have and maintain an efficient weaving process, it is necessary that the reed groove have a desired air flow profile as established at the time of manufacture of the reed.

For more information about our Dynamic Pressure Gauge, please contact:

Lonnie Hooper

864-277-8585

This email address is being protected from spambots. You need JavaScript enabled to view it.